LTC elektro s.r.o company was found in 1991 as the first Czech company with residence in Brno. It belongs among reliable companies with wide range of business fields.

Areas of expertise:

MEASURING AND REGULATION, DEVELOPMENT OF ELECTRONIC DEVICES, SWITCHBOARD PRODUCTION, PROJECTION, BUSINESS AND CONSULTING ACTIVITIES

Main references

2016PRŮMYSLOVÁ KERAMIKA Rájec-Jestřebí– in progress

– controlling of drying kiln for industrial ceramics, remote access

MESIT a.s. Uherské Hradiště

– controlling of crucible furnace for AL alloy

Brano Hradec n. Moravicí, a.s.,

– controlling, visualization and archivation of heat processing of elevating furnace for cast iron

– data scanning, evaluation, transmission for floating analyzer of furnace atmosphere

2015

Alusak Kroměříž

– completion and construction of electric devices – switching stations, cabling, lighting

– controlling of stabilizing furnaces for AL alloy

– controlling of rotating furnaces for AL alloy, cooperation with SOLMET Italy

– implementation of control room, visualization and controlling of CW6, remote access

2014

KOVOLIS Hedvíkov a.s.

– controlling of crucible furnaces for AL alloy, remote access

FAGOR EDERLAN a.s. , Žiar nad Hronom, SLOVENSKO

– controlling of crucible furnace for AL alloy, remote access

KOVOLIT a.s., MODŘICE

– controlling of crucible furnaces for AL alloy

TOP ALULIT BENEŠOV

– controlling of crucible furnace for AL alloy

2013

PD-Refraktories Svitavy

– controlling of trolley furnace for Dinas (S7-300, distributed system, ca. 25 stations and converters using Profibus, visualization – scada CW6, Kepserver, OPC)

KOVOLIT a.s., MODŘICE

– controlling of crucible furnaces for AL alloy

2012

Metso a.s., Přerov

– controlling of regenerative annealing furnace

Alusak Kroměříž

– controlling of stabilizing furnace for AL alloy

SIEMENS sro, o.z. Elekromotory MOHELNICE

– controlling of crucible furnaces for AL alloy

2011

Slovzink, Slovensko

– controlling of furnaces for Zn evaporation – production of white zinc

Metso a.s., Přerov

– controlling of regenerative annealing furnace

MORAVSKÉ KERAMICKÉ ZÁVODY Rájec-Jestřebí

– controlling of tunel kiln for industrial ceramics

MBNS – Kovárna, Brno

– controlling of blacksmith forge 2MW

2010

Alusak Kroměříž

– controlling of roller dryer for Al splinters, controlling of stabilizing furnace

2009

Best Business, a.s. Kunštát

– controlling of laboratory furnace no. 2 for ceramics

Brano Hradec n. Moravicí, a.s.

– controlling, visualization and archivation of heat processing of elevating furnace for cast iron

ČEPRO a.s. Loukov,

– measuring of surface of petroleum products and data transfer to superior system S7-300 using MODBUS-RTU protocol

2008

Železárny Hrádek a.s., Hrádek

– controlling of annealing furnace, visualization of technological process

Žďas a.s., Žďár n. Sázavou

– production and delivery of switchboards and cabling for controlling of regenerative blacksmith gas forge no. 5

2007

Žďas a.s., Žďár n. Sázavou

– production and delivery of switchboards and cabling for controlling of regenerative blacksmith gas forges no. 14, 7, 8

Deza a. s., Valašské Meziříčí

– dioctyl dosage for expedition and racking chemicals to cargo tanks and train tankers

Best Business, a.s., Kunštát

– controlling of shuttle regenerative kiln for ceramics – 1300ºC

Poldi Hütte, a.s., Kladno

– controlling of backsmith heating forge 3,7 MW with regenerative heating

PD Refractories, Velké Opatovice

– controlling of dual-chamber dryer for ceramics with humidity drying

2006

Alusak Kroměříž

– controlling of melting furnace for Al alloy

Žďas a.s., Žďár nad Sázavou

– production and delivery of switchboards and cabling for controlling of regenerative blacksmith gas forge no. 13

US Steel, Košice

– controlling of tunel dryer for ceramics

2005

Poldi Hütte, a.s., Kladno

– controlling of backsmith heating forge 3,7 MW with regenerative heating

HŽP, a.s., Prostějov

– controlling of heating furnace 1,3 MW for automotive leaf springs with regenerative heating

2004

KOVOLIS Hedvíkov a.s.

– system for controlling of electricity consumption ¼ maximum

– measuring of operating fluid leakage of foundry

– controlling of holding furnace for Al alloy

PRŮMYSLOVÁ KERAMIKA Rájec-Jestřebí

– controlling of Starweine burner

2003

KOVOLIS Hedvíkov a.s.

– controlling of holding furnace for Al alloy

COMAX, a.s. Velvary

– controlling of melting furnace for Al alloy – 5 and 10 tons

COMAX, a.s. Velvary

– controlling of propulsion and hydraulics of rotating melting furnace

2002

Kovolit Modřice a. s.

– information system for evidence and processing of operation of casting machines

Prodez a. s.,Valašské Meziříčí, Messer Technogas

– controlling of stacks for oxygen burners of glass furnaces

HETTICH, a.s., Žďár nad Sázavou

– controlling of melting gas furnace for Zn alloy, controling of mobile furnaces for Zn distribution

2001

ČEPRO a.s. Včelná, Bíteš, Bělčice, Hájek

– measuring of surface of petroleum products and data transfer to superior system S7-300 using MODBUS-RTU protocol

TONDACH Česká republika, s.r.o.

– controlling of dual-chamber dryer for construction ceramics

2000

ČEPRO a.s. Smyslov

– measuring of surface of petroleum products and data transfer to superior system S7-300 using MODBUS-RTU protocol

Prodez a. s.,Valašské Meziříčí, Messer Technogas

– controlling of dual regulation line oxygen-natural gas (Sklo Bohemia Světlá n/S)

Kovolit Modřice a. s.

– controlling of holding furnace for Al alloy

1999

ČEPRO a.s. Střelice

– measuring of surface of petroleum products and data transfer to superior system S7-300 using MODBUS-RTU protocol

KOVOLIS Hedvíkov a.s.

– 16 switchboards for electric holding furnaces for Al alloy, full equipment of foundry

Brano Hradec n. Moravicí, a.s.

– data scanning, evaluation, transmission for floating analyzer of furnace atmosphere

Other interesting references in 1995 - 2016

Remet spol. s r.o., Brno

– ongoing measurement of liquid metal surface height in casting machine

– controlling of propulsion of rotating furnaces for Al alloy with remote control of functions

mills for Al alloy – Czech republic, Poland, Slovakia

– controlling of amount of gas melting and holding furnaces for Al alloy

Czech republic, Slovakia, Hungary, Romania

– controlling of stations for increasing biogas pressure

Deza, Zliv, Calofrig Borovany, Sanker (SR), Železárny Hrádek…

– delivery of hundreds security switchboards for burners of tunel furnaces

– delivery of tens switchboards for controlling dryers with STARVEINE burners

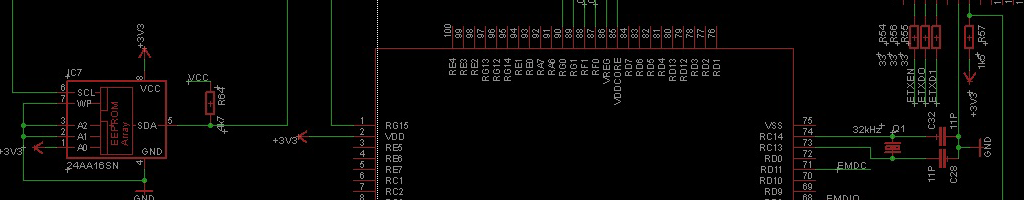

AIS spol. s r. o., Brno

– development and production of modems for communication on private telephone lines in large energetic information system

– development and production of communication boards to PC for energetic information system

– development and production of devices for precise measuring of electrical phase and voltage for energetic information system

Ukrajina, Slovensko

– switchboards for food industry purposes

ČSAV ÚFM

– measuring and regulation of heating temperature for devices with magnetic resonance

VUT FS Brno

– measuring and regulation of temperature of post-combustion device

COMAX Velvary

– controlling of dryer heating for ongoing coil-coating line for sheet of tin

Deza a. s., Valašské Meziříčí

– projection of controlling of industrial waste incinerator

Nová Mosilana (Marzotto)

– repairs of electronics of textile machines and development of control board replacement (power supply for spectrum analyzer, power controlled rectifier …)

– delivery of surveillance system for tracking some nodes of technological process

– delivery of large-dimension information panels

– delivery of 36 measuring converters connected to PC via serial port RS232

– measuring of fabric length on output console

Hydrotech

– controlling of torch for methane incineration – Cyprus

ÚVP Brno

– controlling of tens torches for methane incineration

– tens switchboards for controlling burners

Galvia Český Dub, Realistic K. V., ÚVP Brno

– implementation of heating for galvanizing line

Kovohuť Mníšek pod Brdy

– controlling of propulsion of rotating furnace for Al alloy

– controlling of stabilizing furnaces for AL alloy

Kovohutě Břidličná

– delivery of switchboards for gas lines security

ZSNP Žiar n. Hronom, SR

– tens of switchboards for gas burners security

CAB, SR

– switchboards for gas burners security

Vihorlat Snina, SR

– controlling of gas melting furnace for Al alloy

Cihelna Citherm, Olomouc (Cidem Hranice)

– controlling of heat source for industrial ceramics drying

Cihelna Hodonín

– controlling of heat source for industrial ceramics drying

ALW Olomouc

– controlling of melting and stabilizing furnaces for Al alloy, measuring of surface height using electrodes

Expert and special works

– repairing unique devices, instruments and printed circuit boards with insufficient or missing documentation

Development works

– development and application of programmable automats and panel regulators including software development for logical controlling and communication in networks with superior PC

– development of communication board to PC – 8 serial channels with full operation using communication protocol accoring to customer wish – application in energetics

– development of modems for private lines in energetics

– development of power-supply sources

– development of tens small single-purpose and special devices

– development of several generations of devices for measuring exact time rates in energetics as a follow-up to satellite navigation system GPS with communication to superior units (so called phasor measurement)

– production of VN transformer for gas burners ignition

– development and production of controlling units for Assa Abloy (Besam) door systems

– development of evaluation units for scanning surface for measuring in tanks with petroleum products